Integrated Design in Mechanical Engineering

Integrated design in mechanical engineering is transforming the way machines, systems, and industrial products are developed. By combining advanced CAD tools, simulations, and collaborative workflows, engineers can deliver efficient, sustainable, and innovative solutions faster than ever. This approach allows teams to consider the full lifecycle of a product, from initial concept to final manufacturing, ensuring that every design decision is informed by real-world constraints and performance requirements.

What Is Integrated Design in Mechanical Engineering?

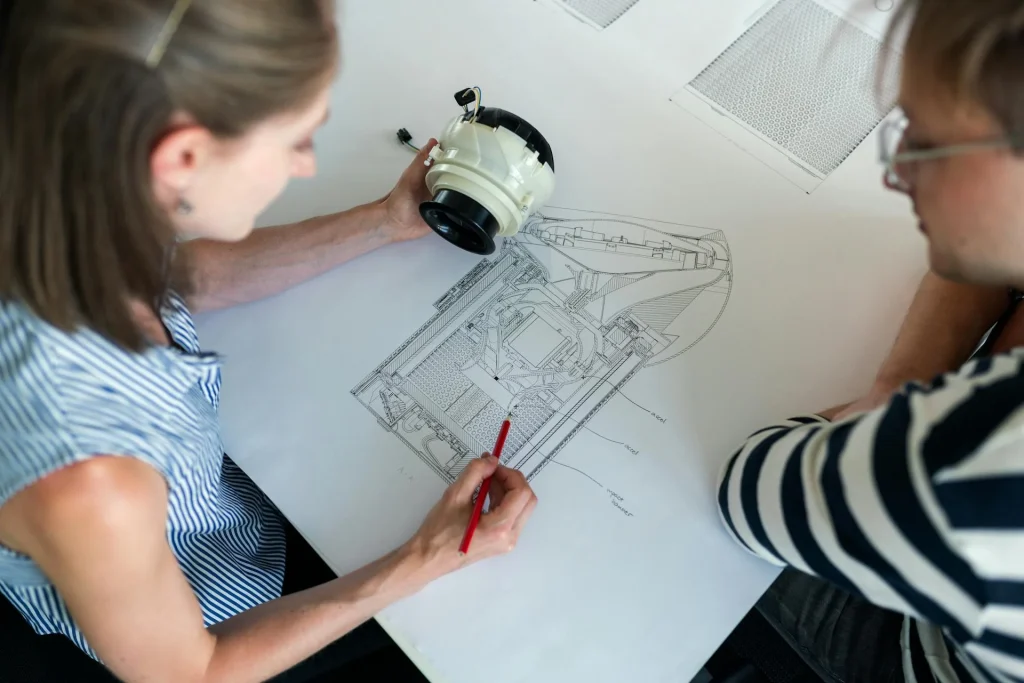

Integrated design in mechanical engineering refers to the use of advanced digital tools such as CAD, 3D modeling, and real-time simulation. Instead of working in isolated phases, engineers collaborate on a shared platform, aligning every stage with the final product. This collaboration ensures that design decisions consider mechanical performance, manufacturability, cost, and environmental impact simultaneously.

📌 Example: A design team working on an automotive engine can run thermal, fluid, and structural simulations at the same time, improving performance and durability before production begins. Additionally, feedback loops allow for iterative refinement, which reduces errors and accelerates project timelines.

Key Benefits of Integrated Design in Mechanical Engineering

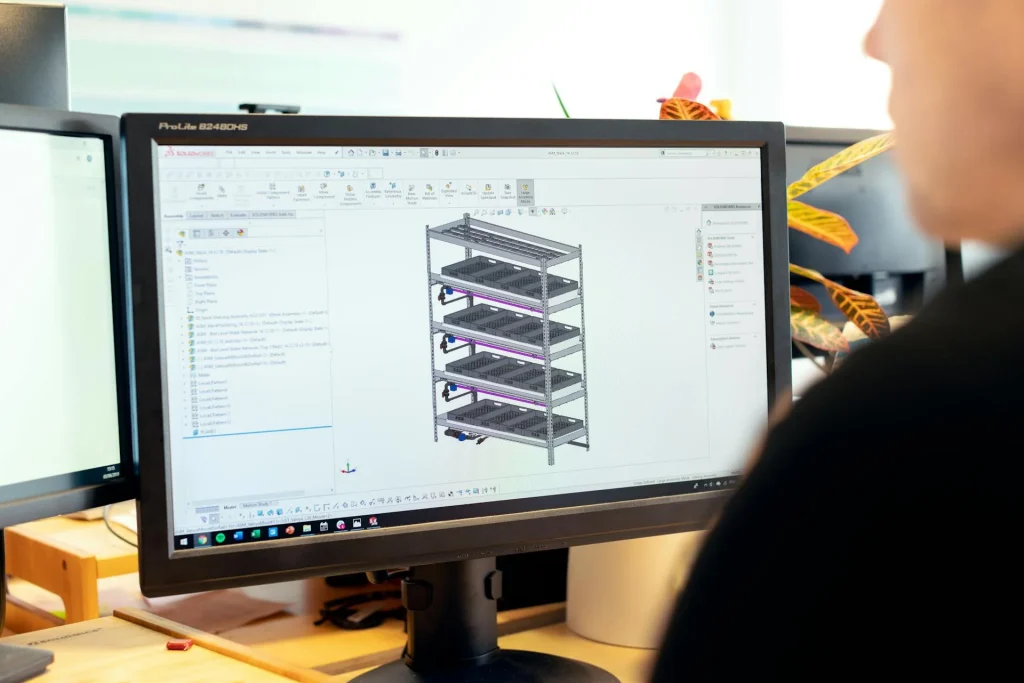

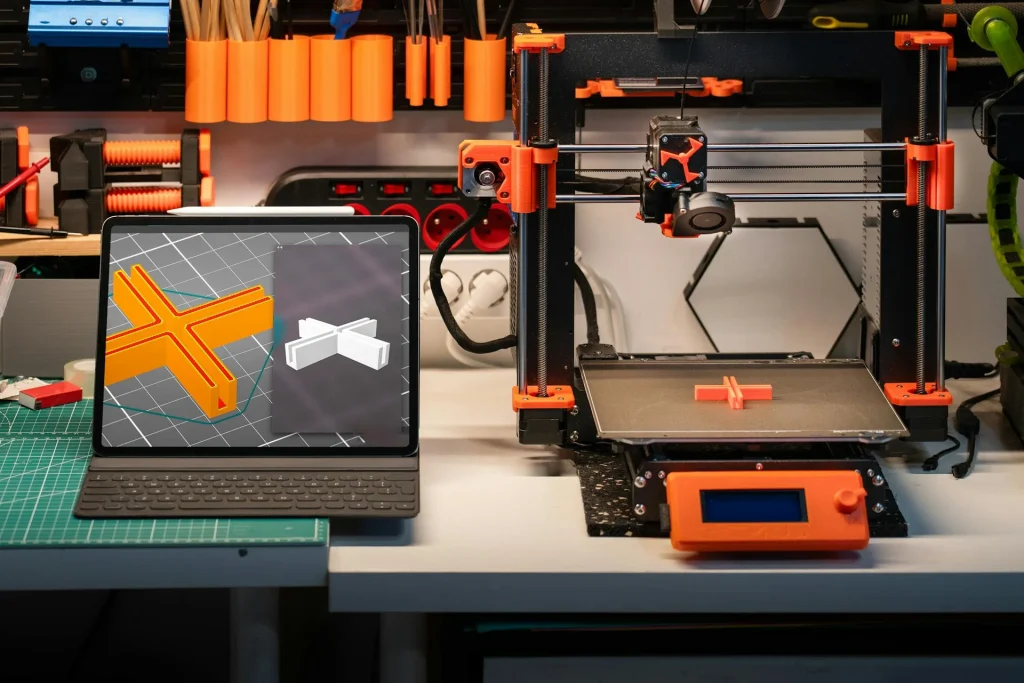

- Faster Prototyping – 3D simulations allow engineers to quickly test multiple design variations, accelerating the prototyping phase.

- Cost Savings – Virtual testing reduces the need for expensive physical prototypes and minimizes material waste.

- Collaboration – Teams from mechanical, electrical, and software disciplines work together on a single platform, ensuring alignment and reducing misunderstandings.

- Efficiency – Early detection of potential issues prevents delays during manufacturing and improves overall project workflow.

- Enhanced Product Quality – By integrating simulations and real-time feedback, products are more reliable, durable, and aligned with industry standards.

👉 Discover how design shapes modern spaces Integrated Design in Architecture.

Real-World Applications of Integrated Design in Mechanical Engineering

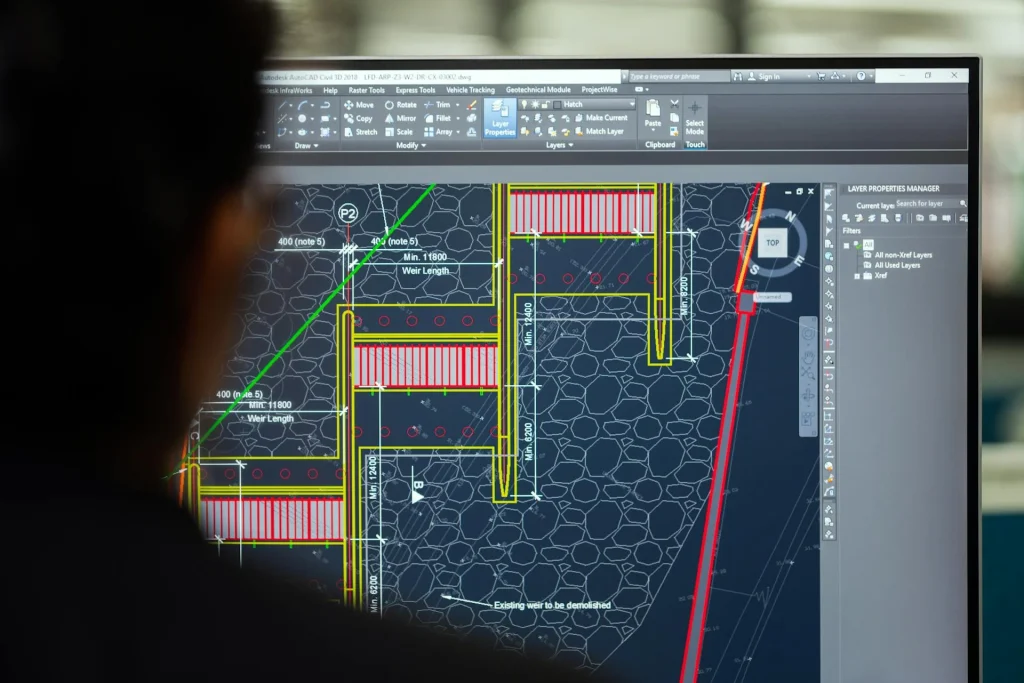

Engineers apply integrated design across multiple industries:

- Automotive – Engineers optimize engines, chassis, and aerodynamic profiles, improving fuel efficiency and performance.

- Aerospace – Lightweight, high-strength components are designed with integrated simulations to meet strict safety and performance standards.

- Manufacturing – Robotics, automation, and precision machinery are developed efficiently through cross-disciplinary collaboration.

👉 For more details, you can explore Siemens NX solutions that enable advanced engineering design.

Conclusion

Integrated design in mechanical engineering is revolutionizing the way engineers develop products. By combining advanced tools, real-time collaboration, and iterative feedback, teams can produce stronger, smarter, and more sustainable solutions. This approach ensures competitiveness in today’s fast-paced industrial environment and supports innovation in every sector, from automotive to aerospace to industrial machinery. Companies adopting integrated design benefit from reduced costs, faster development cycles, and higher quality products that meet both technical and environmental standards.